3D printing for bioceramics

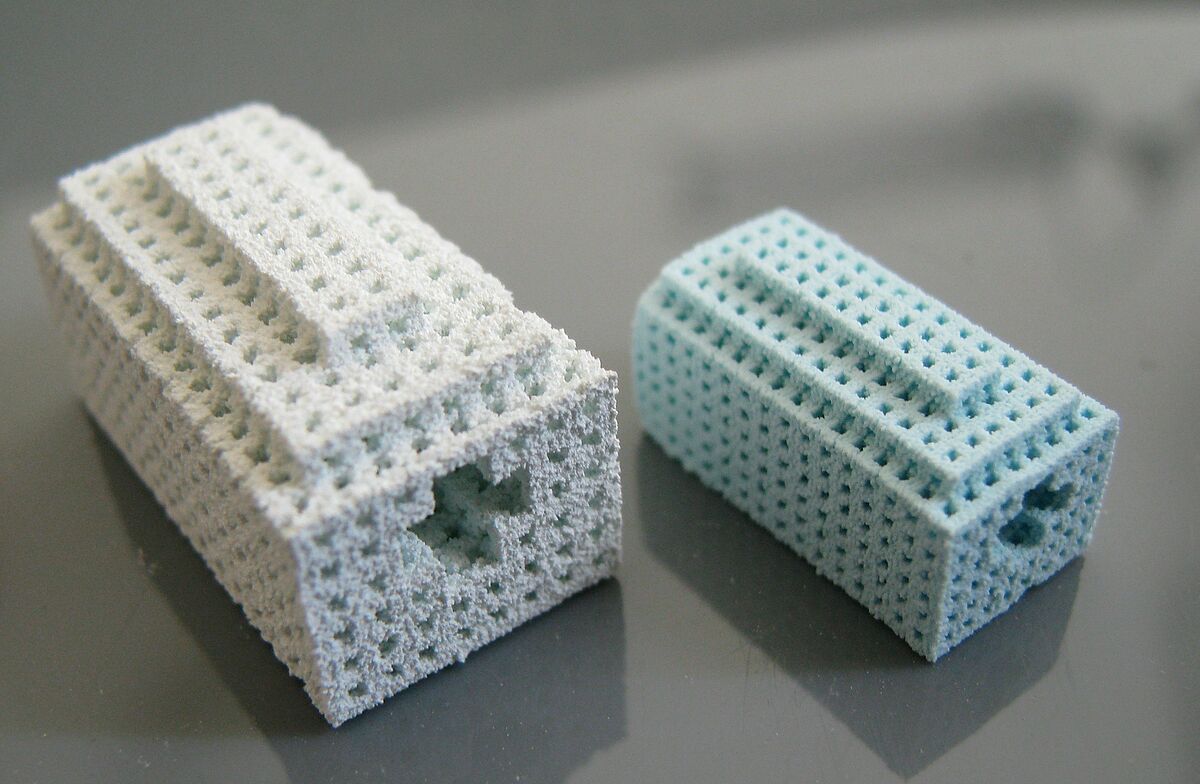

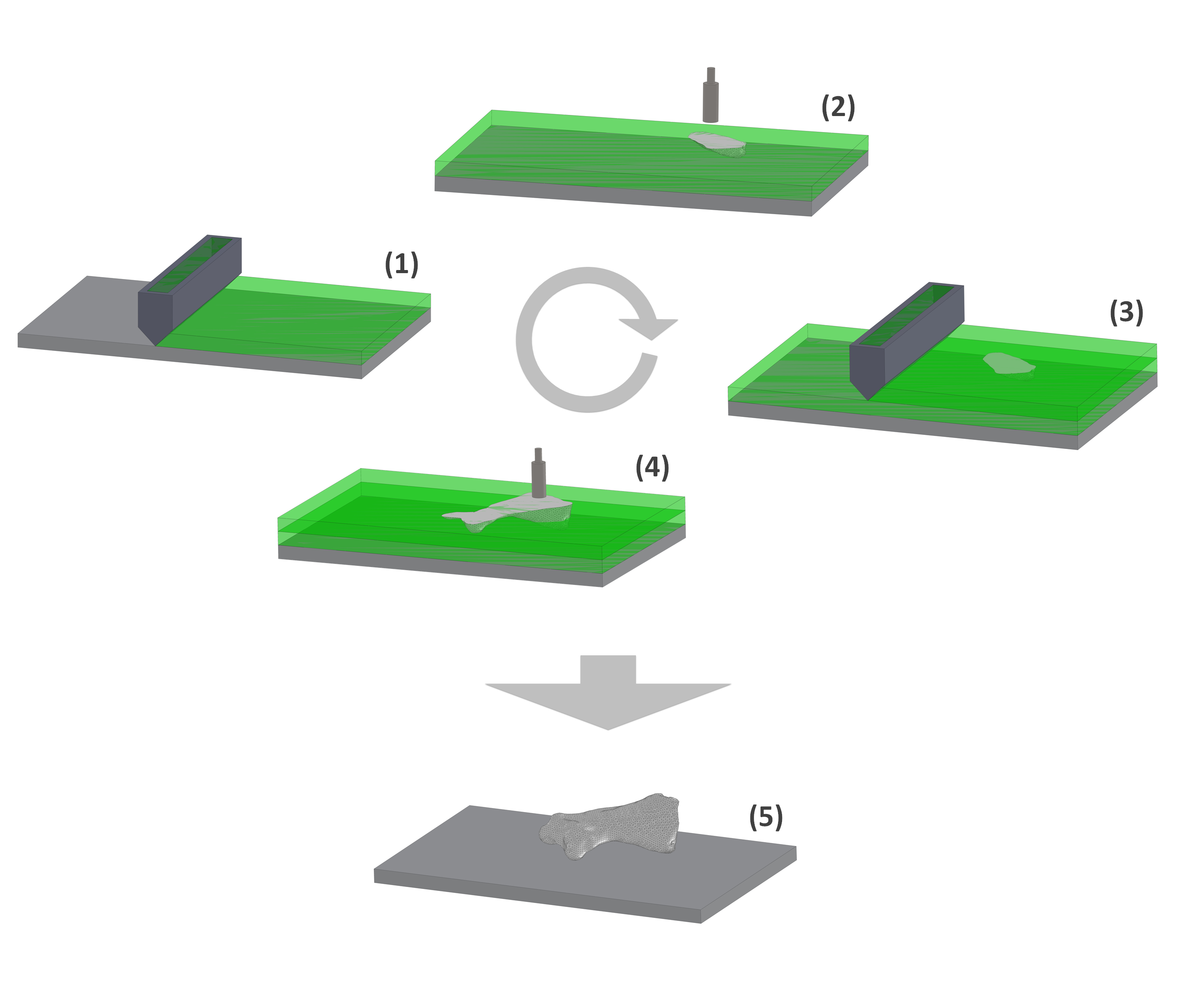

3D printing test systems are used for direct production of patient-specific bone graft substitutes. Three-dimensionally structured, resorbable scaffolds are produced and then seeded with autologous cells (tissue engineering). The scaffolds can be generated using different bioceramics.

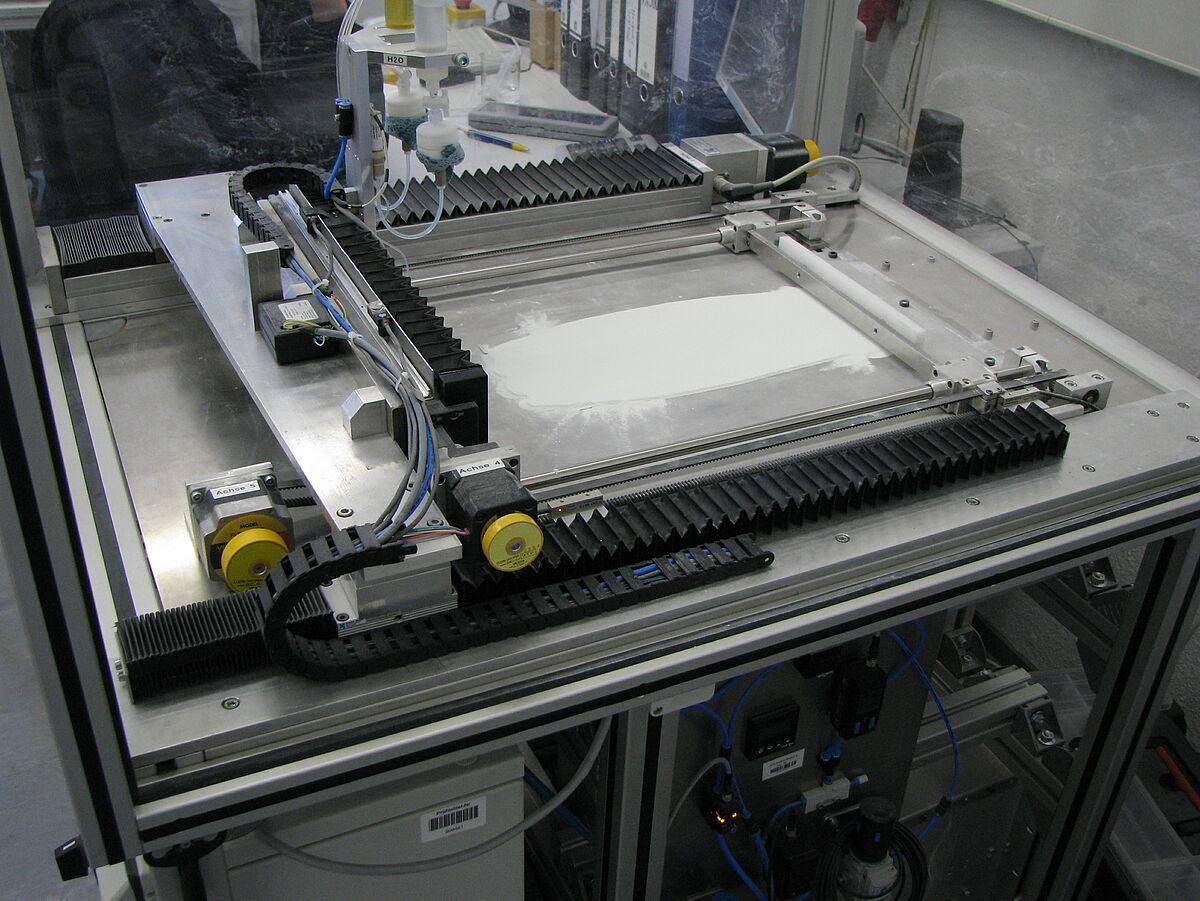

The test rig consists of a storage room, a building space, a level and a printing unit.

After the manufacturing process, the green bodies (see below on the left) are freed from the rest of the loose powder and sintered in a final treatment step. In this high temperature process the parts undergo a material-dependent shrinkage and achieve their final strength.

Contact: Christian Polley M.Sc.

| Building Space L/W/H: | 100 x 100 x 100 mm3 |

| Resolution: | 250 µm x 250 µm |

| Layer thickness: | 250 µm |

| Build speed: | 30 mm/h |

| Data format: | Bitmap |

| Material: | Hydroxylappatit, Tricalciumphosphat, biphasische Keramiken |