Working group leader:

Dr. rer. nat. Abdullah Riaz

Justus-von-Liebig Weg 6

18059 Rostock

Tel.: +49 381 / 498 - 9138

Fax: +49 381 / 498 - 9092

Email: abdullah.riaz(at)uni-rostock.de

Room: UT15

Field-activated sintering/ Spark Plasma Sintering

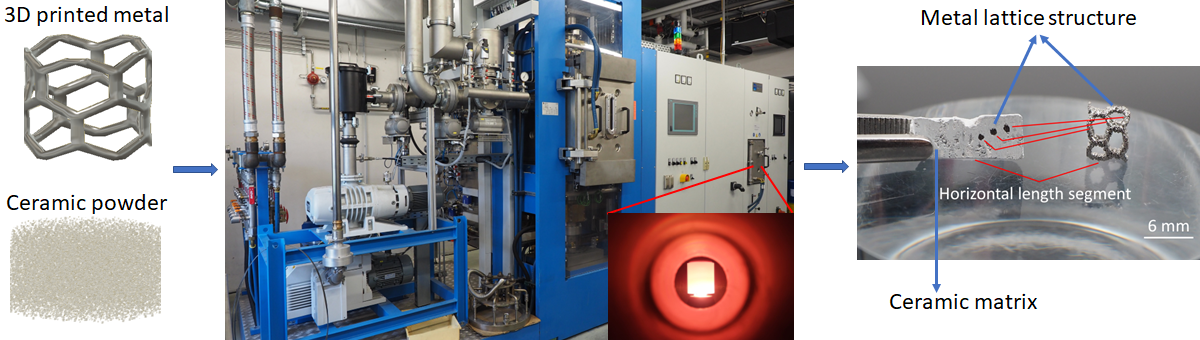

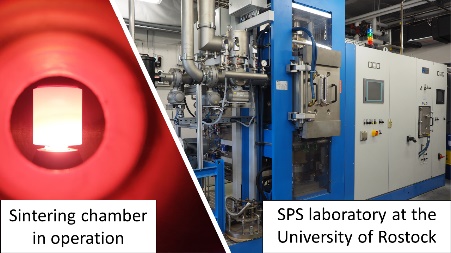

In recent years, innovative processes such as the Field Assisted Sintering Technique (FAST), also known as Spark Plasma Sintering (SPS), have been developed. Since 2010, the University of Rostock has had its own sintering facility, which is equipped with two FAST/SPS systems (HP D5 and D125 from FCT Systeme GmbH Rauenstein, Germany) and a globally unique rapid gas cooling system.

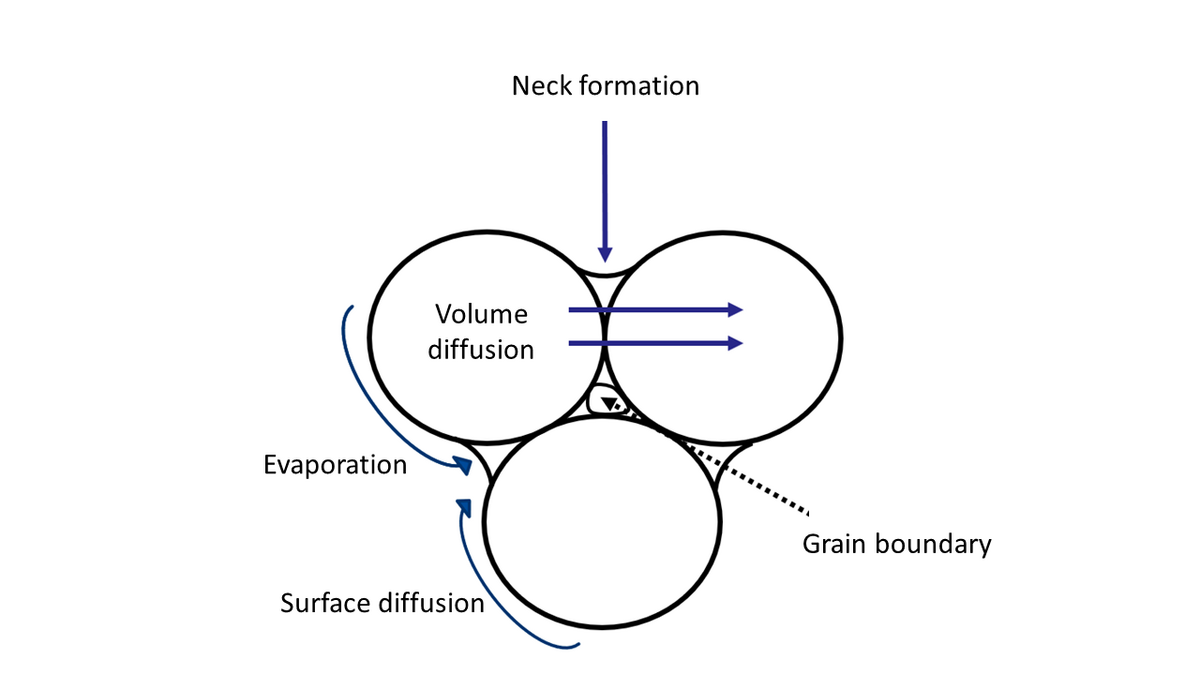

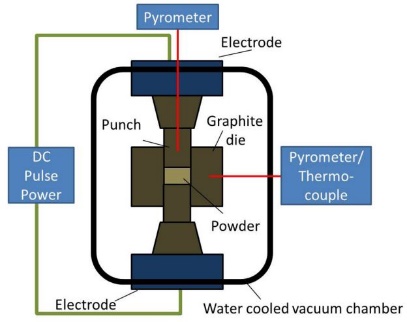

FAST/SPS uses pulsed, directed current in combination with uniaxial pressure to solidify powders. The advantages of this process are cleaner grain boundaries in sintered ceramics, a remarkable increase in the superplasticity of ceramics, higher permittivity in ferroelectrics, improved magnetic and thermoelectric properties of functional materials as well as improved bonding quality or reduced segregation of impurities at grain boundaries.

The research focus of the Chair of Microfluidics using the FAST/SPS laboratory

1. bioactive and piezoelectric materials for multifunctional bone implants

2. high entropy alloys (HEA)

3. coupling of additive manufacturing and FAST/SPS processes

Current research projects

Joint project: Novel interconnected porous piezoelectric ceramic-bioactive glass composite scaffolds for bone tissue engineering – Fabrication and experimental characterization

The DFG project entitled: “Novel interconnected porous piezoelectric ceramic-bioactive glass composite scaffolds for bone tissue engineering – Fabrication and experimental characterization” is being carried out in collaboration with the Chair of Materials Science (Biomaterials), Friedrich Alexander University Erlangen-Nuremberg.

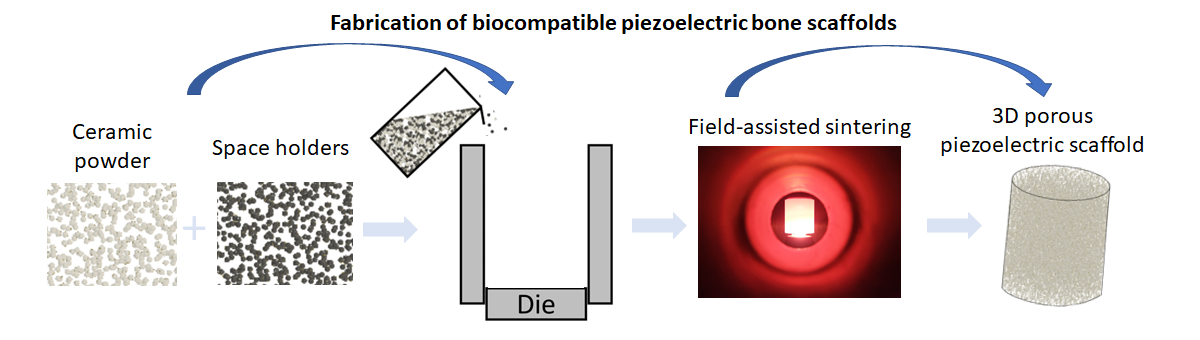

The aim is to create new, interconnected porous nanocrystalline potassium sodium

niobate (KNN) piezoelectric ceramics combined with amorphous pure and copper (Cu)-doped silicate bioactive glasses (BGs) for treating bone defects more effectively than current methods. The primary objective is to achieve sufficient piezoelectric properties in interconnected porous biomaterials with enhanced bioactivity.

Field-Assisted Sintering Technology/Spark Plasma Sintering (FAST/SPS) will be crucial in developing these scaffolds, as the sintering conditions achieved by FAST/SPS are unattainable with conventional sintering methods. This will help maintain the amorphous phase of BGs, ensuring both piezoelectricity and bioactivity. The fabricated composite scaffolds will undergo detailed physical and biological characterization. The biological studies will focus on understanding cell-material interactions.

Principal Investigator: Dr. Abdullah Riaz

Funding:DFG - Deutsche Forschungsgemeinschaft

Project duration: 12/2025-11/2027

Cooperation partners:

Chair of Materials Science (Biomaterials), Friedrich Alexander University Erlangen-Nuremberg, Germany

School of Physics, Conway Institute of Biomolecular and Biomedical Research, University College Dublin, Ireland

SolidBat – Development of a solid-state sodium-ion battery using scalable manufacturing processes for stationary applications

The AiF-funded project "SolidBat – Development of a solid-state sodium-ion battery using scalable manufacturing processes for stationary applications" is carried out in collaboration with the Leibniz Institute for Plasma Science and Technology e.V. in Greifswald and the Chair of Energy Technology at the University of Duisburg-Essen.

The aim of this project is the production of a functional sample of a solid-state sodium-ion pouch cell with an electrode area of 25 cm². This serves as a basis for further developments towards a home energy storage prototype for commercial manufacturing on an industrial scale.

Solid-state sodium-ion batteries are particularly characterized by high operational safety and fast-charging capability. Furthermore, compared to lithium-ion batteries, the use of critical raw materials such as lithium, cobalt and nickel can be avoided.

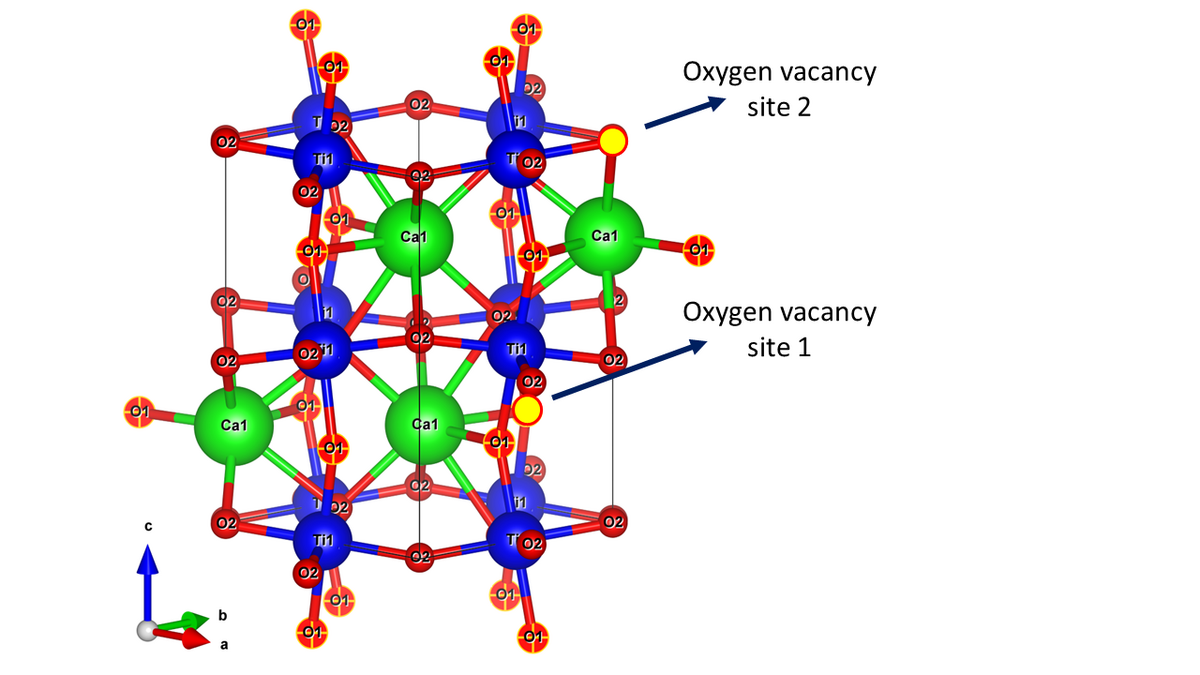

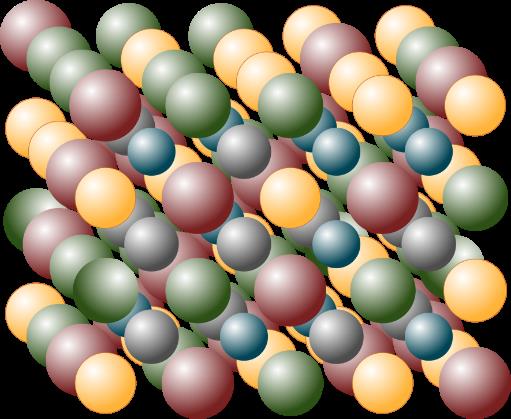

As part of the sub-project, a ceramic powder material is synthesized at the Chair of Microfluidics using a solid-state reaction. This material belongs to the class of NaSICON ceramics (chemical formula Na₃Zr₂Si₂PO₁₂) and shows high sodium ion conductivity. The solid electrolyte is then manufactured using a field-assisted sintering process (FAST/SPS). Scanning electron microscopy and X-ray diffractometry are performed on the solid electrolyte which is subsequently provided to the project partners for assembly of the pouch cell.

Person in charge: Christian Biermann, M.Sc.

Funding: Allianz für Industrie und Mittelstand e.V. (AiF) – Forschungsnetzwerk Mittelstand, Industrial Collective Research (iGF)

Project duration: 11/2025-10/2027

Project partners: Leibniz Institute for Plasma Science and Technology e.V. (INP Greifswald); Chair of Energy Technology, University Duisburg-Essen

Completed research projects

The AiF-funded CatHEA project ("Metal-supported membrane electrode units with high-entropy alloy cathodes for alkaline polymer membrane water electrolysis") is being carried out in collaboration with the Chair of Materials Engineering / University of Rostock, Leibniz Institute for Plasma Research and Technology Greifswald and the Center for Fuel Cell Technology Duisburg.

The overall aim of this project is to produce a functional model of a low-cost, high-performance, precious metal-free membrane electrode unit for alkaline electrolysis.

As part of the sub-project, various high-entropy alloys (HEA) are mechanically produced at the Chair of Microfluidics and characterized using X-ray diffraction, electron scanning microscopy and spectroscopy. The focus is on HEA alloys that show high catalytic activities for the hydrogen evolution reaction (HER). If necessary, the HEA alloys will be adapted and further developed in consultation with the partners to improve their suitability for the overall project objective.

The HEA alloys with different sample diameters (10 - 100 mm) are sintered using the field-assisted sintering technology (FAST) and the spark plasma sintering process (SPS) at the Chair of Microfluidics. The sintered HEA samples are then used as targets for physical vapor deposition (PVD).

Author: Alexander Ahrend M.Sc.

Funding: AiF - Forschungsnetzwerk Mittelstand, IGF - Industrielle Gemeinschaftsforschung

Project duration: 11/2022-06/2024

Cooperation partners: Leibniz Institute for Plasma Research and Technology e.V. (INP Greifswald); Center for Fuel Cell Technology GmbH (ZBT Duisburg)