Working group leader:

Dr.-Ing. Georg Schnell

Justus-von-Liebig Weg 6

18059 Rostock

Tel.: +49 381 / 498 - 9093

Fax: +49 381 / 498 - 9092

Email:

Room: UT16

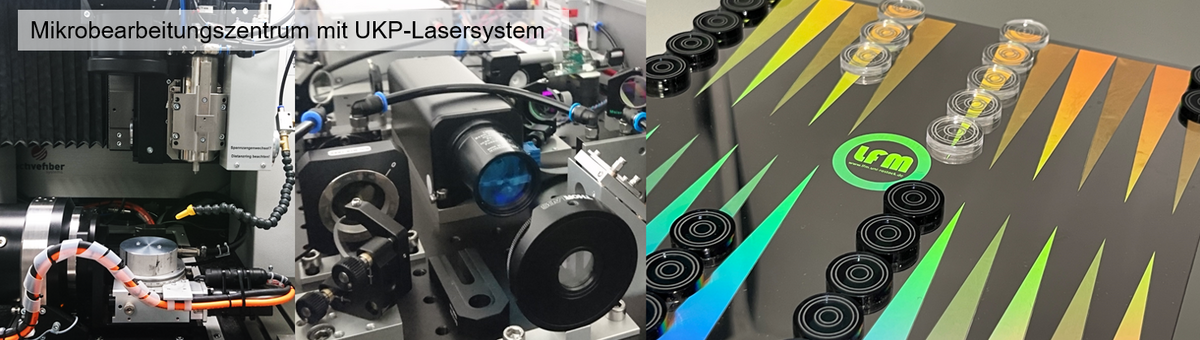

Laser micromachining and surface functionalization

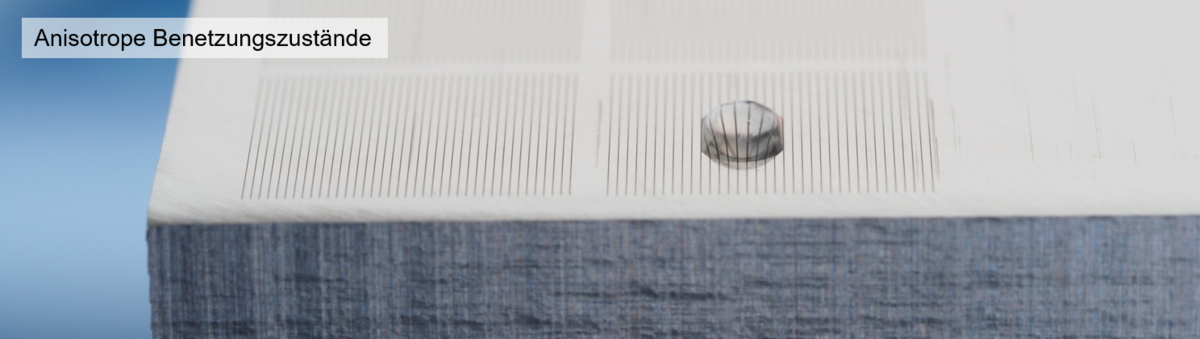

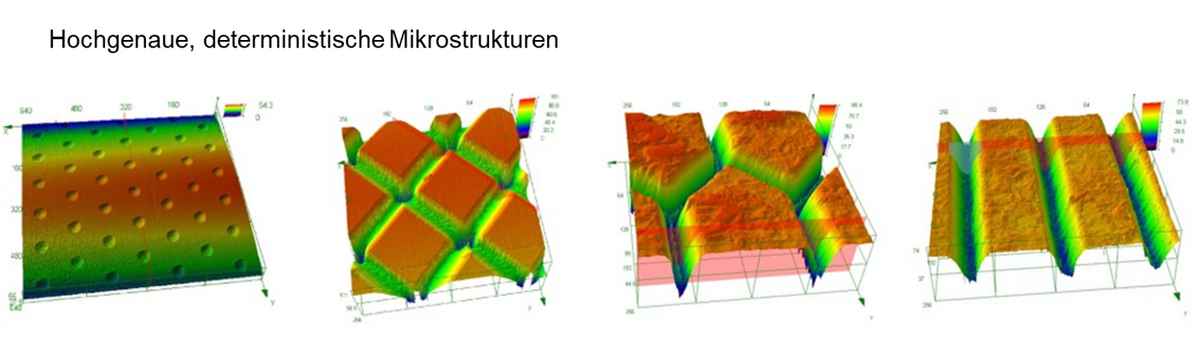

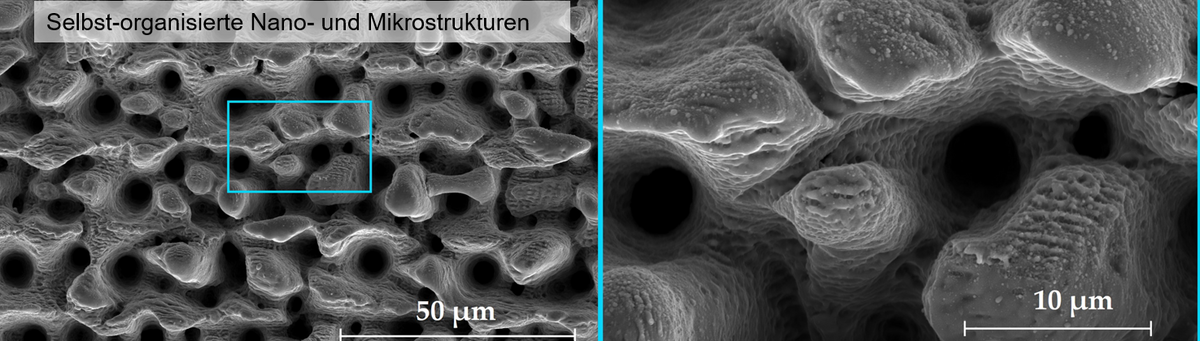

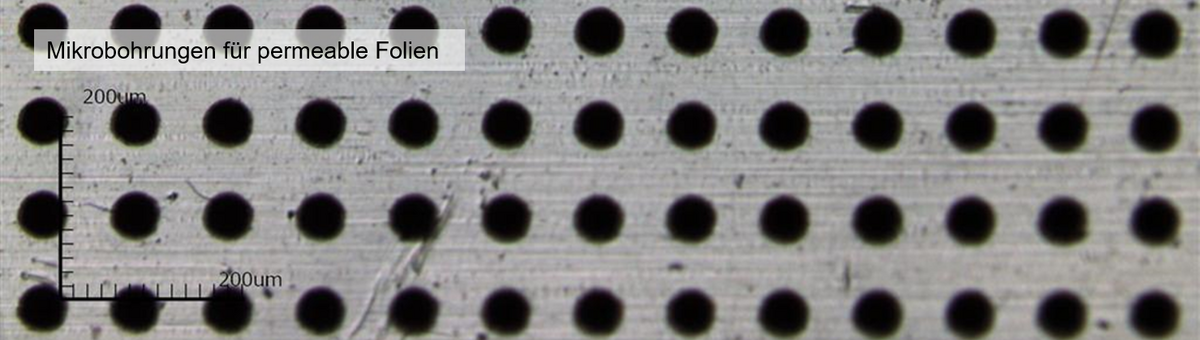

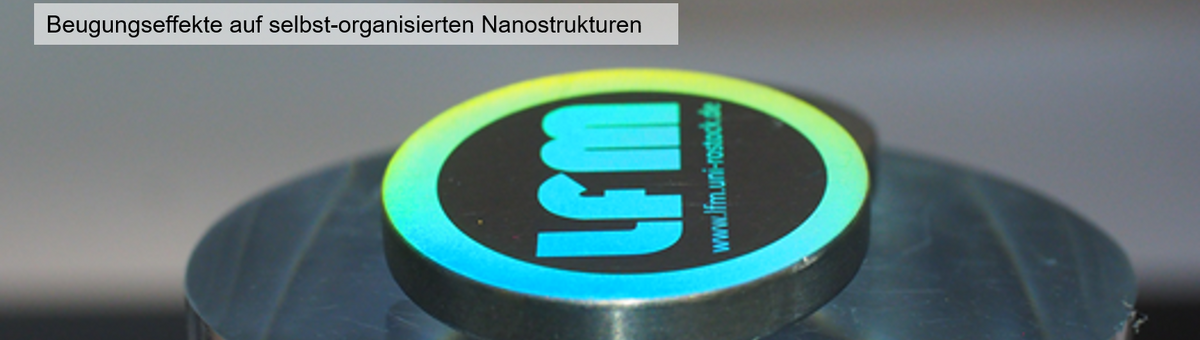

Femtosecond laser processing (fs laser processing) offers us unique possibilities for processing surfaces at the Chair of Microfluidics. The extremely short interaction time between light and material - one femtosecond corresponds to a millionth of a billionth of a second - enables the almost athermal processing of almost all materials. On the one hand, this allows high-precision laser-inscribed patterns to be generated with a resolution well below the size of a human hair. On the other hand, self-organized structures grow in the laser spot, similar to the focal point of a magnifying glass, which makes it possible to create structures down to the nanometer range.

The Laser Micromachining and Surface Functionalization (LaserSurf) working group develops surfaces with superhydrophobic and anti-adhesive properties, microstructures to reduce friction and wear, or interfaces to prevent biofilms in medical and marine biological environments with national and international partners. In particular, the focus is on developing scanning strategies for realizing self-organized structures that are confusingly similar to natural surfaces and thus offer a very high potential for biomimetic surfaces. Based on fs laser processing, we can also cut and perforate materials and precisely adjust physical, chemical, and crystallographic surface properties, such as those required for hardening surfaces.

.

Current Research projects

The aim of the project is to develop a microscope that can be used for process and quality assurance by means of AI, so that the parameterization of the laser system as well as process control and monitoring can be significantly simplified and the need for expert knowledge and personnel deployment can be reduced. The area of application focuses on roughness and structure classes of surfaces in USPL material processing. The implementation is carried out through the development of suitable microscope hardware for image processing, extensive practical tests on roughness and structure classes, associated AI model developments and holistic functional integration into a prototype.

Development of a system for image-based process control and automated parameter determination for USPL surface treatment based on CCD data.

The LFM sub-project aims to develop and validate an evaluation and training protocol for data fusion of image data from reflected light microscopy (CCD data) with sensor data from confocal microscopy (roughness data). The aim is to develop AI models and use them to recognize and classify surface structures and roughness values on the basis of CCD image data and to distinguish them with sufficient certainty. The integration of decision support based on the AI models into the higher-level machine control system with a focus on process automation and decision support as well as user-friendliness is to be carried out in the final work step together with the project partner.

Responsible for the project: Dipl.-Ing. Robert Thomas

Funding: Federal Ministry of Economic Affairs and Climate Action

Project duration: 06/2024 - 05/2027

Project partner: GFH GmbH, Deggendorf

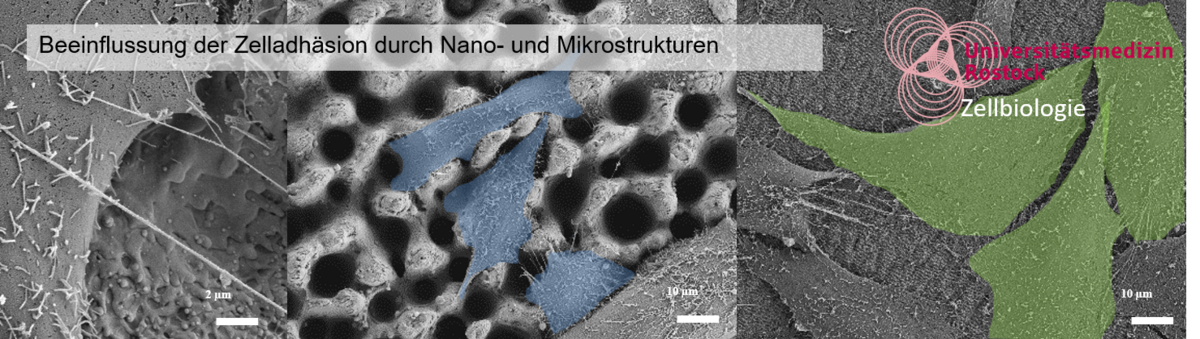

The stability of a dental implant is an essential factor for successful implantation, which is achieved through integration into the hard and soft tissue. The attachment of the tissue is facilitated by the roughness created on the implant surface. However, one problem here is the increased inflammation of the tooth bed (peri-implantitis) between the crown of the dental implant and the gums. This is triggered by a microflora of periodontal pathogens. The project aims to create a hierarchically structured glass solder surface with optimized tissue attachment and, at the same time, anti-adhesive properties for pathogens. The approach used is the micro- and nanostructuring of glass solder surfaces using ultrashort pulse lasers.

Person in charge:Fiona Hartung M.Eng.

Project duration: 04/2023 - 09/2025

Funded by: Bundesministerium für Wirtschaft und Klimaschutz (BMWK)

Partners:

Dentallabor Moss GmbH, Hamburg

Universitätsklinikum Hamburg-Eppendorf

Completed research projects

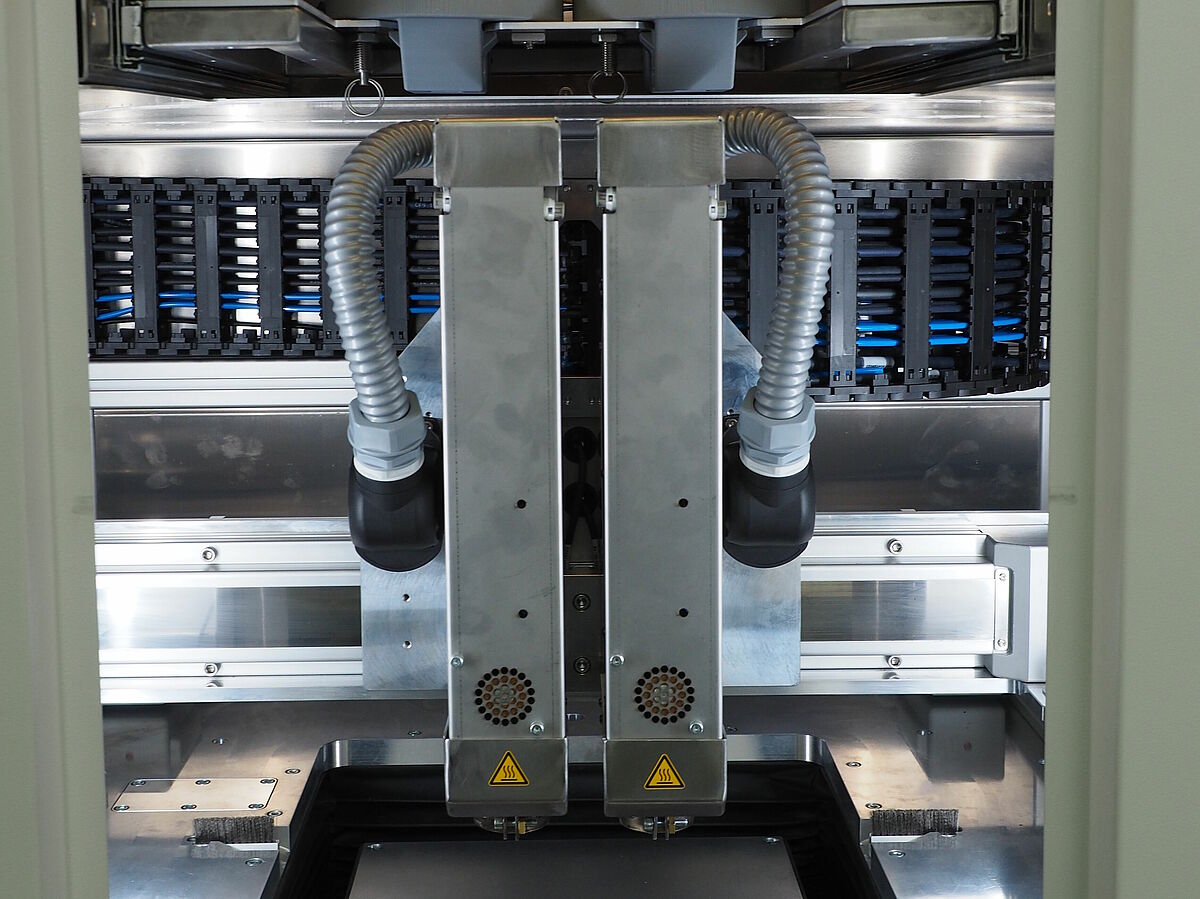

The project aims to develop a novel process for the nano- and microstructuring of injection molds using ultrashort pulsed lasers. The superhydrophobic wetting behavior of the processed surfaces is

intended to improve the demolding behavior of the injection-molded components, thereby reducing rejects and reducing maintenance and cleaning cycles. For the automated structuring of tools, a robot-guided ultrashort pulse laser is to be developed in collaboration with Robot-Technology GmbH, which, in conjunction with intelligent trajectory control and a 3D scanner control principle, can structure complex, three-dimensional tools with high precision and optimum accessibility. Newly developed gating systems and structured venting channels with self-cleaning properties to reduce clogging result in high-quality injection molds with an increased service life.

Person in charge: Dipl.-Ing. Robert Thomas

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Project duration: 05/2021-02/2024

Partners: ROBOT-TECHNOLOGY GmbH, EBS Werkzeugbau GmbH

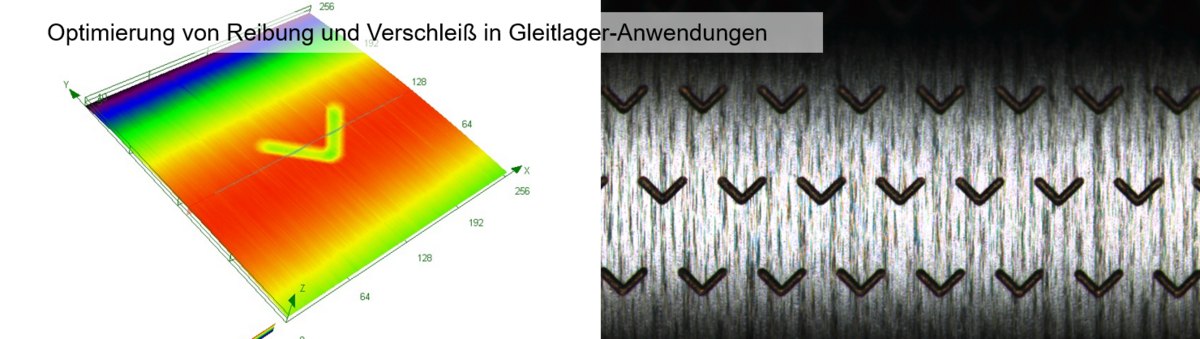

For various reasons, journal bearings are superior to rolling bearings in heavy machinery, particularly in the paper industry. However, the weak point is the wear-intensive start-up behavior of highly loaded journal bearings. Therefore, this project aims to develop an innovative process for the surface structuring of journal-bearing shells using ultrashort pulse lasers. The microstructures in the bearing shell are intended to improve the tribological behavior of the journal bearings to reduce wear during operation and significantly increase the longevity of the bearings. Three different effects are to be achieved by the microstructure: Increasing the lubricating film thickness between the friction partners, absorption and removal of abrasion particles, and function of the microstructures as lubrication pockets to reduce interfacial friction. Among other things, these measures are intended to minimize the breakaway torque and the friction coefficient of the contact partners in the mixed friction range and accelerate the transition to the liquid friction range.

Person in charge: Dr.-Ing. Georg Schnell

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Project duration: 09/2020-12/2022

Kooperationspartner: lOS Miesbach GmbH, 83714 Miesbach

The collaborative project "Wear-optimized hip endoprostheses" is part of the MikroLas growth core. The joint project also consists of three sub-projects. The sub-project "Investigation of shear thickening through microstructuring" focuses on investigating the rheological processes in the lubrication gap of microstructured implant surfaces by developing a measurement method for determining shear thickening. With this microstructuring of the implant surfaces, the project aims to reduce wear from a tribological perspective. The project aims to microstructure articulating endoprosthesis components to functionalize them tribologically and influence the rheological properties of the lubricating film. In Germany alone, around 180,000 hip operations are performed every year. Increasing the service life of the implants used is of great interest and should be achieved by reducing wear. This reduction in wear can be achieved by structuring the implant's surface. Using ultrashort laser pulses, burr-free structures with dimensions in a few micrometers are to be created on the surfaces, which fulfill two functions. On the one hand, the microstructures serve to maintain the tribologically valuable lubricating film and, on the other, they are intended to trap and render harmless abrasion particles that occur in the lubrication gap of the endoprosthesis and induce so-called three-body wear. Both aspects are intended to increase the service life of hip endoprostheses.

Person in charge: Dr.-Ing. Philipp Drescher

Project duration: 9/2017 –12/2020

Partners: PtJ – Projektträger Jülich

Im Verbundprojekt „Biotechnische Mikrozahnringpumpen“ des Wachstumskerns MikroLas werden Mikrozahnringpumpen mit hohen Anforderungen für den Diagnostikmarkt und für Hersteller von Pharmaprodukten entwickelt. Dabei sollen kleine bis kleinste Mengen z. T. hochagressiver Medien präzise dosiert oder kontinuierlich in Anlagen und Prozessen gefördert werden, die den behördlich geforderten Hygienestandarts und Zertifizierungen der Prozesse genügen. Im Augenmerk liegen dabei neben dem der Reinigungsdauer für den Kunden, dem Pumpenaufbau hinsichtlich des Hygienic Design mit funktionalisierten Oberflächen und der Auswahl biokompatibler Werkstoffe einschließlich angepasster Fügetechniken. Im Teilprojekt 6.2 ist eine Erhöhung der Lebensdauer der Reibpaarung Welle-Lager beabsichtigt. Dafür sollen die tribologischen Eigenschaften (Reibkoeffizient, Verschleiß) der Welle-Lager-Paarung durch die Aufbringung von Mikrostrukturen mittels ultrakurzer Laserpulse optimiert werden. Gelingt es den Verschleiß zu minimieren, sind längere Standzeiten der Mikrozahnringpumpen und trotz höherer Anschaffungskosten eine gestiegene Wettbewerbsfähigkeit der Produkte zu erwarten.

Bearbeiter: Georg Schnell M.Sc.

Projektlaufzeit: 9/2017-12/2020

Projektträger: PtJ-Projektträger Jülich

Kooperation: HNP Mikrosysteme GmbH, Schwerin