Working group leader:

Dipl.-Ing. Philip Tempel

Justus-von-Liebig Weg 6

18059 Rostock

Tel.: +49 381 / 498 - 9115

Fax: +49 381 / 498 - 9092

Email:philip.toellner(at)uni-rostock.de

Room: 16

Additive Manufacturing - Applications

Additive manufacturing (AM) - also widely referred to as 3D printing - is the general term for technologies in which materials are successively bonded together to produce physical objects according to the specifications of 3D model data. It differs significantly from conventional manufacturing processes in that material is applied rather than removed. In addition to increased design freedom, the greatest potentials of additive manufacturing include functional integration in particular. This means several components can be combined, and new functions can be integrated into an existing component.

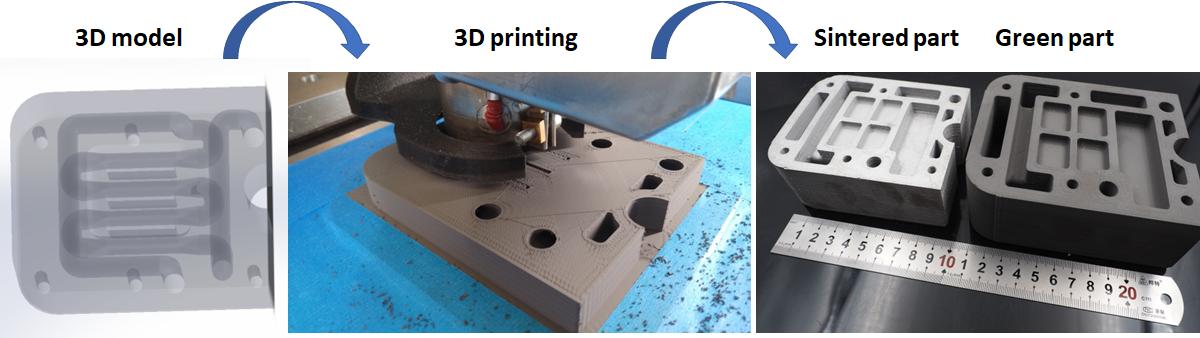

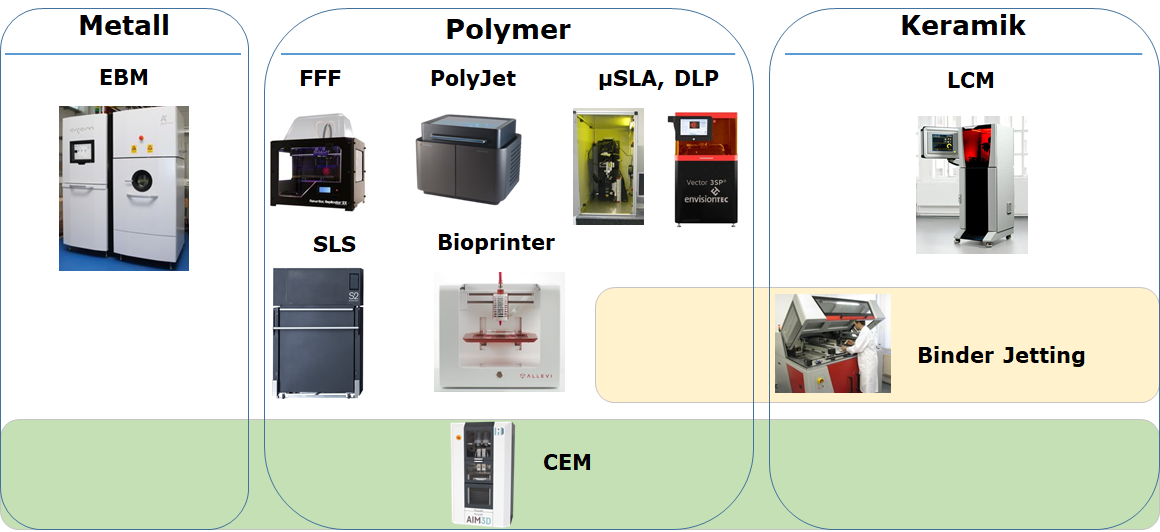

The requirements for the components and the material determine the choice of the additive manufacturing process. Starting with the application level (prototyping, tooling, manufacturing), the required material up to the dimensions and tolerances, the suitable process can be worked out successively. The Chair of Microfluidics' equipment includes a wide range of additive manufacturing processes to process polymers, metals, and ceramics. Some processes require a multi-stage manufacturing process. This means that further steps, such as sintering, are necessary to produce the final material properties after shaping. The figure below illustrates the equipment of the department divided into material classes. For example, processes such as CEM (Composite Extrusion Modeling) and LCM (Lithography-based Ceramic Manufacturing) can process multiple material classes but are also subject to the multi-step manufacturing route.

Current research projects

Development of basic 3D printing parameters for the voxelfill process

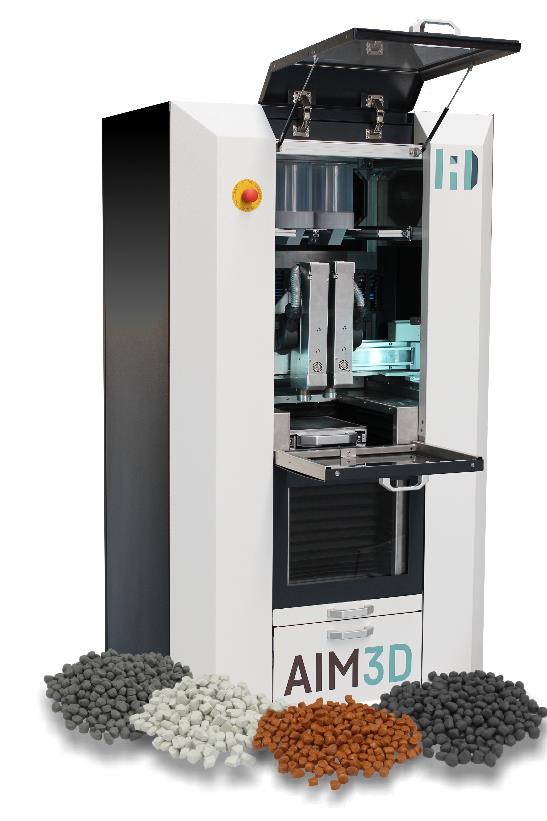

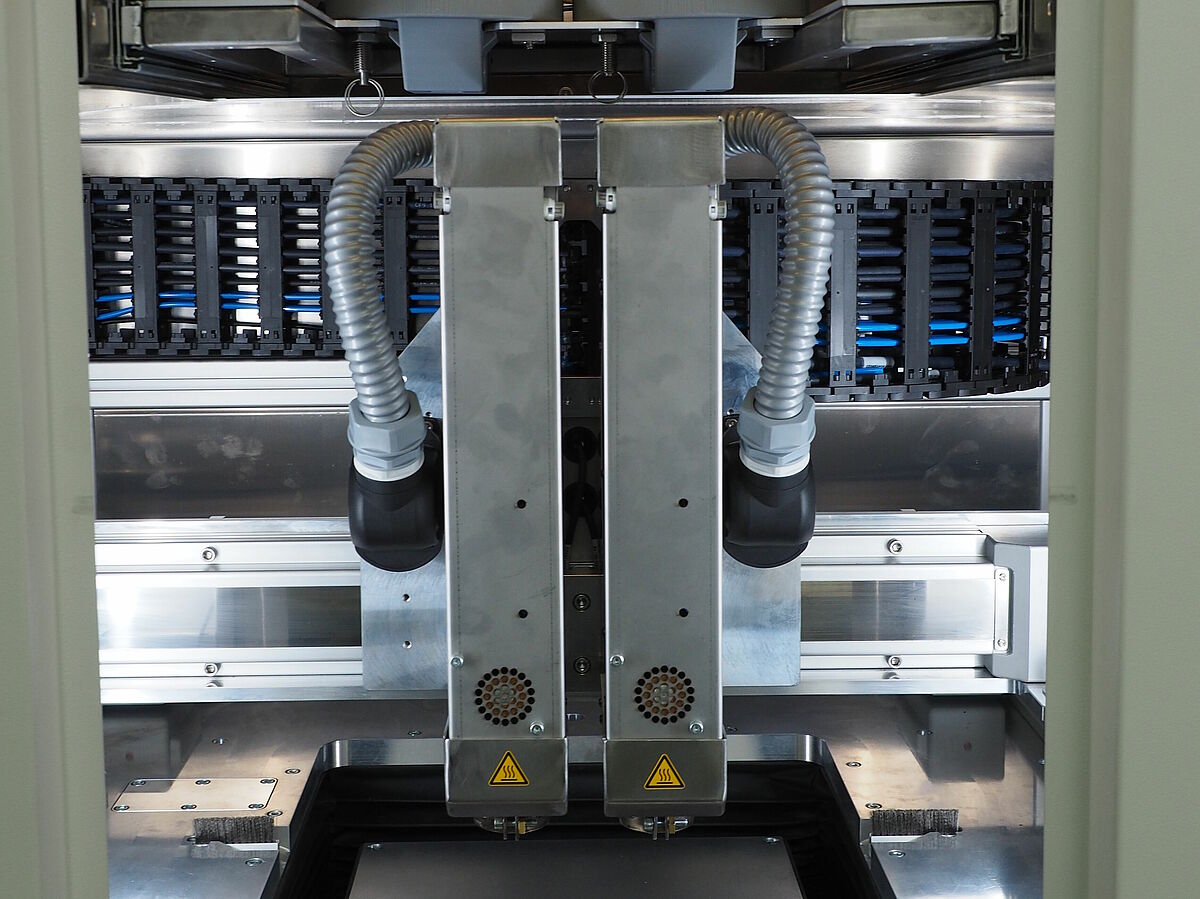

In close cooperation with the 3D printer manufacturer newAIM3D GmbH, Rostock, a new and already patented process called ‘Voxelfill’ is being established for the granulate 3D printing process in order to improve component quality, particularly with regard to stability in the build-up direction.

Extrusion-based additive manufacturing processes are one of the first and most popular forms of 3D printing. Known since the 1980s as fused deposition modelling (FDM), which can be translated as filament deposition, hundreds of 3D printing systems have since come onto the market.

With very few exceptions, FDM printers deposit thermoplastic material in a specific pattern on a two-dimensional plane that runs parallel to the print bed and is usually referred to as the x-y plane. Three-dimensional shapes then ‘grow’ along the build direction (z-axis) by layering a series of two-dimensional patterns on top of each other.

Due to this layered construction method, additively manufactured components have an anisotropic character. This means that the mechanical properties of the components have a strong directional dependency - the strength within a layer is generally higher than the adhesion between the individual layers. FDM objects are rarely printed as solids due to the high filament consumption and time required. However, printed hollow bodies - i.e. only with an outer shell - are also unsuitable for most applications, as they are not robust and break under load. The so-called infill represents a middle ground between solid and hollow bodies. This infill is a repeating structure inside the object that is used to fill the 3D object.

The hybrid solution designed by NEW AIM3D combines a strand deposition process with an injection moulding process that is intended to significantly reduce anisotropy through a cross-layer approach. Under the brand name Voxelfill, this approach no longer involves injection moulding components exclusively layer by layer, but rather by using so-called voxels (volumetric pixels) as volume areas across layers. In the first step of this newly designed process, the infill is replaced by a pattern of defined capsule structures. These define the boundaries of the cross-layer volume elements that are to be injection moulded in the second step. The arrangement of the cross-layer voxels is of crucial importance in this 3D printing strategy. When filling the volume areas, not all voxels may be injection moulded in one plane, as this would again result in a weak point in the Z direction at the ‘seam’ of the voxel plane.By staggering the volume elements at half the height of the voxels, a kind of ‘brick bond’ is created in the component. The flow of force in the component is redirected, thereby increasing the strength. In addition to the significant increase in strength, the elasticity of the components in the Z-direction is also improved. As a hybrid injection moulding extrusion process, Voxelfill also increases the cost-effectiveness of conventionally fully filled components enormously. The printing time required for a fully filled component is significantly lower with volume elements from the Voxelfill process than with a pure strand lay-up process, while at the same time achieving higher strength.

The focus of the Chair of Microfluidics at the University of Rostock is on basic process engineering and parametric investigations. Various materials are analysed for their processability using the voxel fill process. Suitable materials are analysed in detail for a parallel modelling and simulation of the voxel fill process. Density tests and mechanical characterisation of the components are used to develop optimised parameter configurations in order to achieve the most stable process possible and maximum mechanical stability.

Contact Persons: Alexander Ahrend M.Sc, Tim Dreier M.Sc, Dipl.-Ing Philip Tempel

Project Duration: 05/2024-05/2026

Co-operation partner: NEW AIM3D GmbH, Rostock

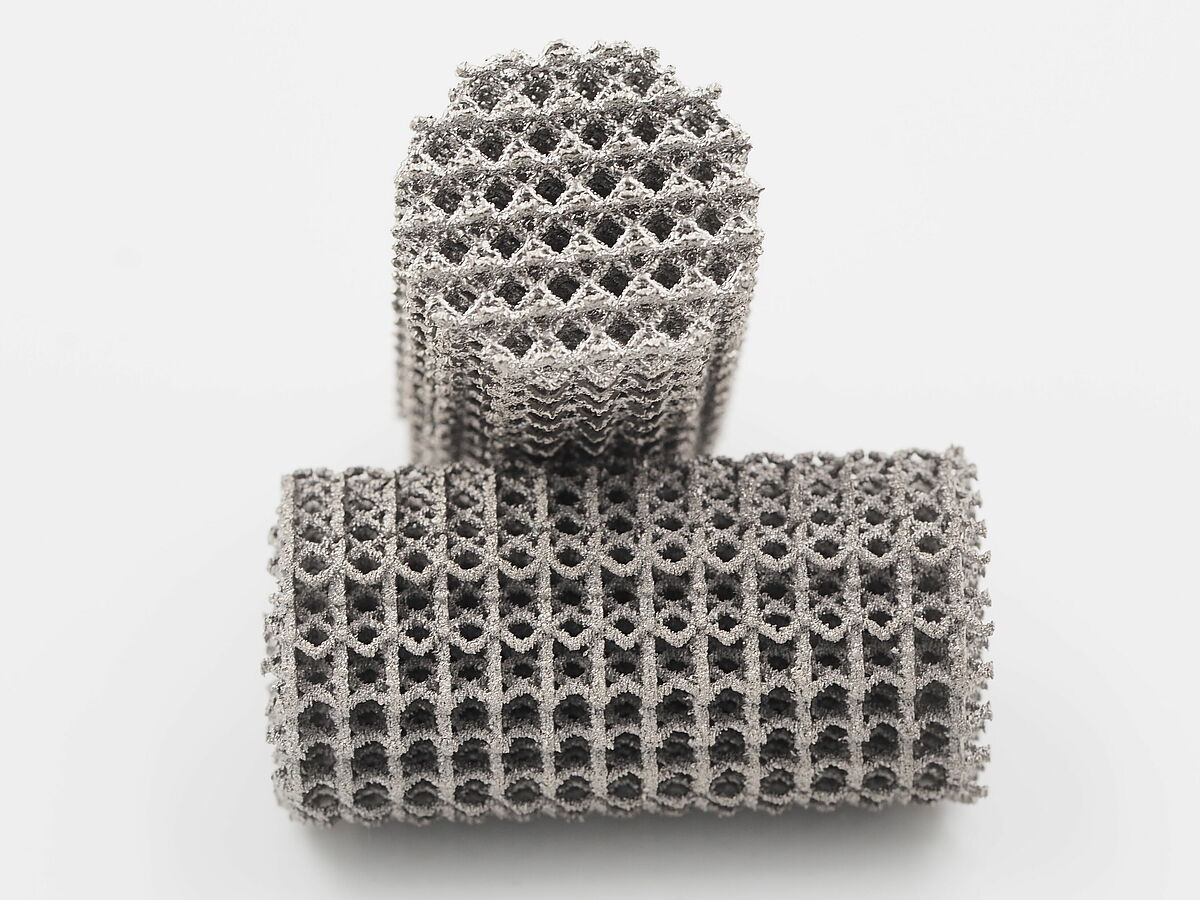

System Development for the Modification of Porous Components Using Plasma-Enhanced Coating (PECVD) for Non-Destructive Density Measurement

The goal of this project is to develop an automatic system for modifying porous green, brown, and final components using PECVD (Plasma-Enhanced Chemical Vapor Deposition), which will be employed in non-destructive, production-integrated density measurement according to the Archimedes principle. Using PECVD, a functional coating in the nanometer range is applied to components without contact. This functional layer will have multiple functions. On one hand, it can act as a barrier against the intrusion of liquids into porous bodies, and on the other hand, it can create a defined surface with adjustable surface energy that is well wettable, thus improving gravimetric measurement.

The Chair of Microfluidics will focus on the development, additive manufacturing, and characterization of porous PECVD-coated components for non-destructive density measurement. The PECVD coating of the components will be carried out by the Leibniz Institute for Plasma Research and Technology e.V. (INP), which is a project partner in this consortium. The transfer of scientific findings into an industrial, automated system, as well as the integration into a gravimetric density measurement procedure, will be carried out by the second project partner, Dimensionics GmbH.

The automation of the coating process for various additive and porous components (green, brown, and final parts) will enable faster examination of component samples through gravimetric measurement, with higher measurement accuracy and lower error susceptibility due to reduced measurement distortion. This is fundamental for the intended use of the validated coating process and the tested demonstrator in industrial manufacturing plants for gravimetric density determination, even of relatively porous green and brown parts. Such an autonomous and precise overall system for component coating and gravimetric density measurement as an independent solution within industrial production lines is the ultimate goal.

Project Lead:Dr. rer. nat. Abdullah Riaz

Project Duration: April 2024 – December 2025

Funding: Ministry of Economic Affairs, Infrastructure, Tourism, and Labour M-V, Operational Program for the European Regional Development Fund in Mecklenburg-Western Pomerania in the funding period 2021 to 2027 (EFRE-OP M-V).

Project Partners:

- Dimensionics GmbH

- Leibniz Institute for Plasma Research and Technology e.V. (INP)

Finished research projects

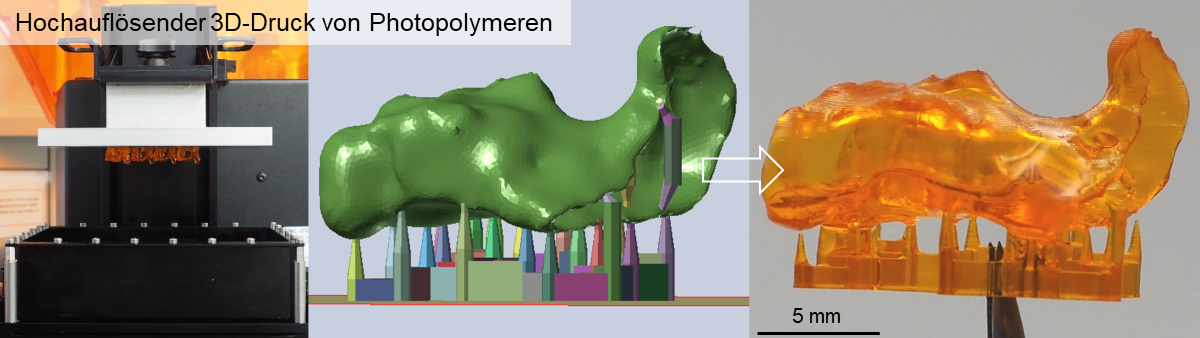

The project aims to develop an additively manufactured jaw implant with a time-controllable release of active ingredients to support the healing process and osteogenesis of the jaw bone.

The implant will be manufactured using a hybrid 3D printing process. A corresponding active ingredient is introduced into the polymer implant to support the healing of the implant and the bone formation. This is incorporated into special active ingredient depots in the implant during the printing process and then released in the tissue by diffusion over a controlled period of time.

In cooperation with the project partners, the model of a jaw implant will be created and printed with novel photopolymers and provided with the active ingredient depots in an appropriately defined size and position. For this purpose, a combined microstereolithography facility will be set up accordingly.

The polymer implant described is intended to greatly reduce the side effects of conventional jaw implants made of titanium. To achieve this, mechanical properties that are as similar as possible to the natural jaw bone are sought. Osteosynthesis is to be promoted by appropriate surface design and the targeted release of the incorporated active ingredient.

Person in charge: Ahmed Sannan M.Sc.

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Project duration: 09/2021 – 02/2024

Partners:

- M.C. Medizintechnik-Export GmbH & Co. KG,

- MEGADENTA Dentalprodukte GmbH,

- Institut für Biomedizinische Technik der Universitätsmedizin Rostock

ZUKUNFT - Cell carriers to support cultured, new meat technology ‘Development of economically and ecologically sustainable cell carriers for cell-based meat products’

In the cooperation project, Innocent Meat GmbH, in partnership with the Chair of Microfluidics, is developing an elementary building block on the way to sustainable, industrially produced, cell-based meat products for the bioeconomy.

Scaffolds, also known as cell carriers or microcarriers, are artificially created scaffold-like structures on which adherent cells can be cultivated in vitro. In order to be able to develop a scalable process at a later stage, the cells must be able to be used in fully automated bioprocesses. This requires scaffolds that provide sufficient surface area for the production of large cell masses and can be used in bioreactor systems. The scaffolds must also be made of a material that can be safely consumed by the consumer.

The project is investigating different processes and materials for the production of cost-efficient, scalable and biodegradable scaffolds and evaluating them for ongoing development in the bioeconomy. The aim is to produce two functional samples of scaffolds using cryogelation and electrospinning.

Researcher: Tim Dreier M.Sc.

Project duration: 09/2022 - 08/2024

Funded by: Federal Ministry of Education and Research (BMBF)

Collaborative partner: Innocent Meat GmbH

Development of a process-integrated parameter analysis system for additive manufacturing systems based on artificial intelligence

The joint research project aims to develop a process-integrated parameter analysis system for additive manufacturing systems based on artificial intelligence. To this end, hardware and software components are being developed which, on the one hand, support and improve quality assurance in the additive manufacturing process and, on the other hand, optimize the process itself. A data analysis system that can be integrated into an additive manufacturing system is being developed on the hardware side. The data analysis detects, analyzes, and monitors relevant process parameters and can use artificial intelligence (AI) algorithms to detect unfavorable process behavior during the 3D printing process at an early stage and initiate optimization strategies. The software component is based on cryptographic blockchain technology. It defines the interfaces for visualizing the analyzed process parameters and digitally, decently, and transparently documents specific parameters. This is intended to enable certified additive component manufacturing.

The combination of AI-based data analysis during manufacturing and cryptographic software for quality documentation enables a completely new, holistic, and intelligent quality assurance concept in additive manufacturing. Joint research and development work is being carried out on this topic with the collaborative partner as part of the joint project.

.

Person in charge: Dipl.-Ing. Erik Westphal

Project duration: 01/2020 - 06/2023

Development and implementation of analytical methods for the experimental validation of gravimetric density measurements on additively manufactured components.

The joint research project aims to develop an innovative system for automated, non-destructive density determination of additively manufactured components based on the gravimetric principle, especially for industrial quality assurance processes. For this purpose, infiltration media, which are necessary for gravimetric density measurement, are optimized with regard to rheological properties, wettability, and long-term stability. Furthermore, analytical methods for density determination of additively manufactured components will be investigated for correlations to the new, automated system, which are currently considered industry standard (micrograph analyses, micro-CT analyses, etc.). Investigations will be conducted on additively manufactured metallic, ceramic, and plastic-based components.

The new system will enable automated and non-destructive determination of component densities with high accuracy, particularly suitable for industrial quality assurance processes and production-integrated measurements. Quality assurance regarding the density and porosity of additively manufactured components will thus become highly precise and cost-effective. To make this possible, knowledge of technological fundamentals for gravimetric buoyancy measurement and the rheological properties of the infiltration media used is indispensable. Furthermore, comparisons with established quality assurance processes are necessary to validate the new system to form the basis for a technically mature and attractive product. Joint research and development work is being carried out on these focal points with the collaborative partner as part of the joint project.

Funded by: Ministerium für Wirtschaft, Arbeit und Gesundheit (M-V), Operationelles Programm für den Europäischen Fonds für regionale Entwicklung in Mecklenburg-Vorpommern in der Förderperiode 2014 bis 2020 (EFRE-OP M-V)

Partners: DIMENSIONICS GmbH

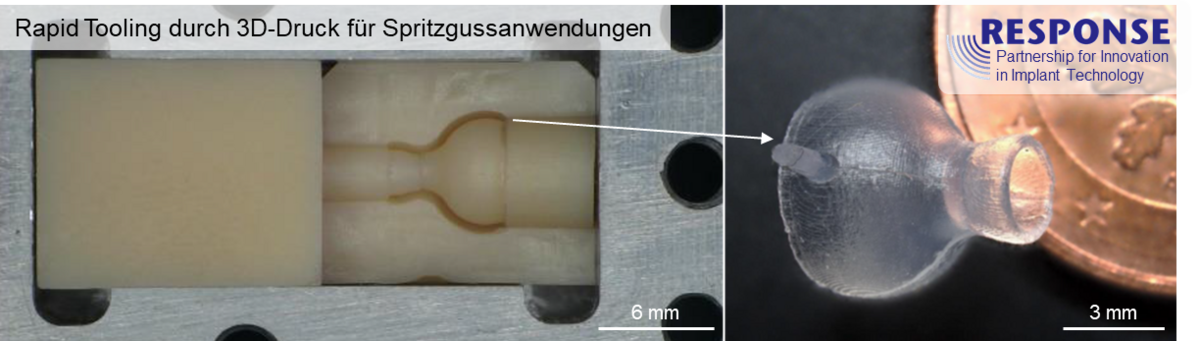

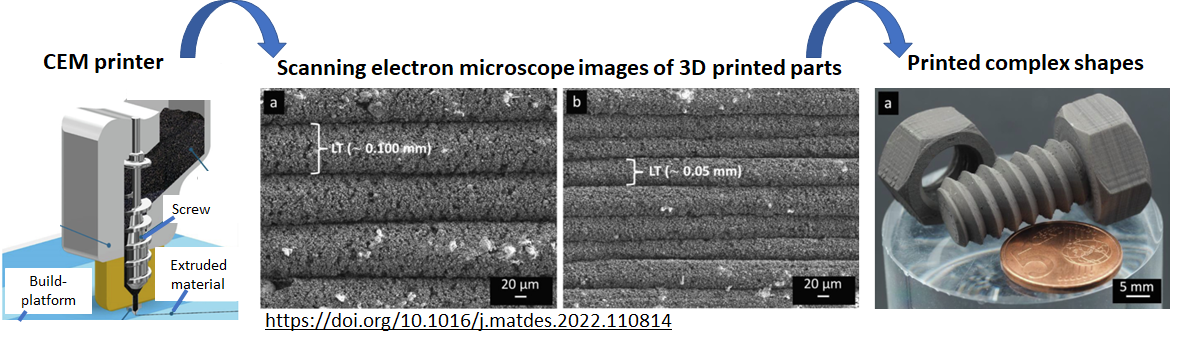

Composite extrusion modeling (CEM) is an additive manufacturing process using feedstocks of plastic binder and metal powder familiar from metal injection molding (MIM). This process can be used to rapidly produce complex metallic components after the necessary debinding and sintering processes.

The cooperative project aims to develop a new process chain for the cost-effective and rapid production of injection molds. Until now, up to eight weeks have been required to produce an injection molding tool. The development of this project is intended to reduce the lead time to about five days.

The approach of using the CEM process to manufacture the tool molds is to be pursued to achieve this. This process, which is still a relatively new method for manufacturing additively produced components, offers the potential to manufacture equivalent tools much faster than conventional toolmaking, thanks to high build rates. The process can then be used to reduce both material and machine costs while circumventing the problems of additive manufacturing about residual stresses and material adjustments on individual machines. Tools can be manufactured 4 to 8 times faster and, at the same time, more cost-effectively in this innovative way.

Person in charge:Dr. rer. nat. Abdullah Riaz

Project duration: 04/2021 – 10/2023

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Partners: Stenzel MIM Technik GmbH

Within the scope of the joint project, a high-speed, large-volume printer for processing ceramic feedstocks in the CEM process is being developed in close cooperation with the company AIM3D GmbH.

The aim is to develop an additive manufacturing process enabling industrial users to produce a few large or many small ceramic components in parallel for the first time. In

In contrast to conventional production, the costs for small quantities can thus be drastically reduced for small quantities. In addition, the additive manufacturing process enables shapes that were previously impossible or only possible with great effort, such as cavities or special infill structures for weight reduction.

The joint project can be divided into three task packages:

* Feedstock development, production and testing.

* CEM 3D printing parameter development and component manufacturing

* Implementation of an intelligent print head

Within the scope of the print parameter development, commercial CIM feedstocks on the market will be examined for their processability. In addition to the analysis of the printed components, the debinding as well as the sintering behavior of the different materials will be investigated. Furthermore, in addition to using conventional CIM feedstocks, a ceramic feedstock is developed at the chair and tested with other mechanical test methods.

These investigations aim to achieve a stable printing process for practical components with the required geometric and mechanical properties. In addition, theoretical and experimental investigations are being carried out to develop a print head for the CEM process further.

Person in charge:Tim Dreier M.Sc.

Project duration: 10/2019 - 02/2023

Funded by: Ministerium für Wirtschaft, Arbeit und Gesundheit (M-V), Operationelles Programm für den Europäischen Fonds für regionale Entwicklung in Mecklenburg-Vorpommern in der Förderperiode 2014 bis 2020 (EFRE-OP M-V)

Partners: AIM3D GmbH

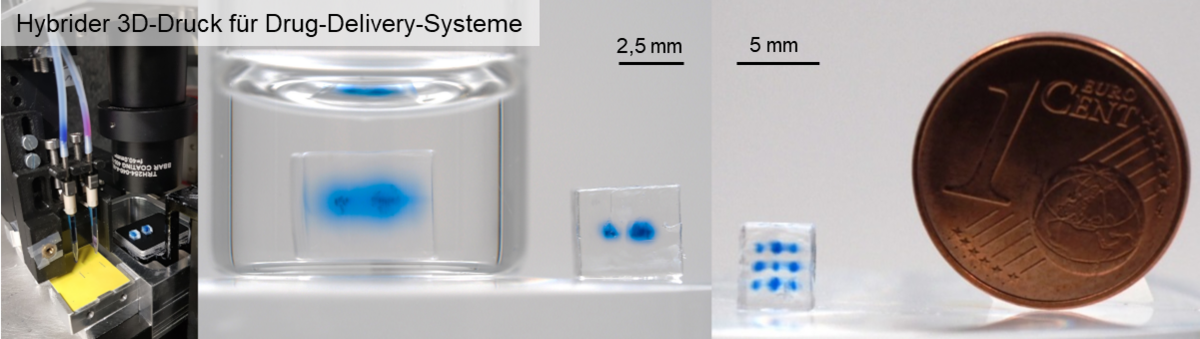

The aim of the research project is to develop drug delivery systems (DDS) with time-controlled drug release. These are intended to enable implant-based, local administration of active ingredients and combinations of active ingredients with specific predefined release mechanisms. For the production of these DDS, a new 3D printing process is required, which will result from the combination of microstereolithography and inkjet technology. This process will be used to create the basic body of an implant via stereolithographic crosslinking and, in the same process, drug loading via inkjet modules. The resulting drug depots will enable controlled and predictable drug release, as properties such as drug concentration can be adjusted during the process.

Person in charge: M.Sc. Jan Konasch

Project duration: 01.09.2017 - 31.08.2019

Composite extrusion modeling (CEM) is an additive manufacturing process using granular starting materials familiar from powder injection molding. Metal and ceramic components can be additively manufactured by means of connected debinding and sintering processes.

Within the scope of the project, feedstocks optimized for the CEM process are to be developed on the basis of a polyamide binder system. The aim is to manufacture pure copper and cold-work steel components using an additive manufacturing process for the first time. A systematic development of an overall process is to be realized by modeling, which describes the relationships between the process and material parameters that can be influenced and their influence on the end product.

Developing a ceramic release layer in powder form after the sintering process is aimed at avoiding the manual or machining separation of the support structures that is necessary in many 3D printing processes.

Person in charge: Erik Sebastian Schmidt M.Sc.

Project duration: 02/2019 - 11/2022

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Partners: MiMtechnik GmbH, Schmalkalden

Development of an inkjet technology for selective glass solder coating of dental implants

The aim here is to develop implants that not only have a long service life, but also heal well in the bone, cause few complications and, if possible, can also be used in difficult conditions. Optimization can and will be achieved in the future primarily by modifying the surface of dental implants. However, current implant surfaces have a geometrically non-directional surface according to the random principle of structuring, which is produced by sandblasting, etching and/or coating. To date, hybrid implants have been coated manually or semi-automatically using airbrush processes. A new process based on inkjet technology is to be developed to selectively coat an existing component with a newly developed glass solder suspension..

Person in charge: Sebastian Eilek M.Sc.; Pedram Azizi M.Sc.

Project duration: 01/2019 - 12/2021

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Partners: Dentallabor Moss GmbH; Universitätsklinikum Hamburg-Eppendorf

The aim of the project is to develop an additive manufacturing process (3D printing process) for the production of metallic components (composite extrusion modeling). First, green parts are additively manufactured from a metallic composite material using a cost-effective extrusion process - similar to the fused deposition modeling (FDM) process. The parts are then removed from the 3D printer and sintered in a sintering furnace. This creates a solid metallic material composite. As neither conventional FDM devices nor the known composite materials are suitable for such a process, both an extrusion system consisting of a print head and material feed and a suitable composite material are being developed in collaboration with the cooperation partner.

Person in charge: Clemens Lieberwirth M.Sc.

Project duration: 03/2015 - 31.08.2017

Funded by: Bundesministerium für Wirtschaft und Energie (BMWi)

Partners: Bernhardt Kunststoffverarbeitung GmbH 3dk.berlin