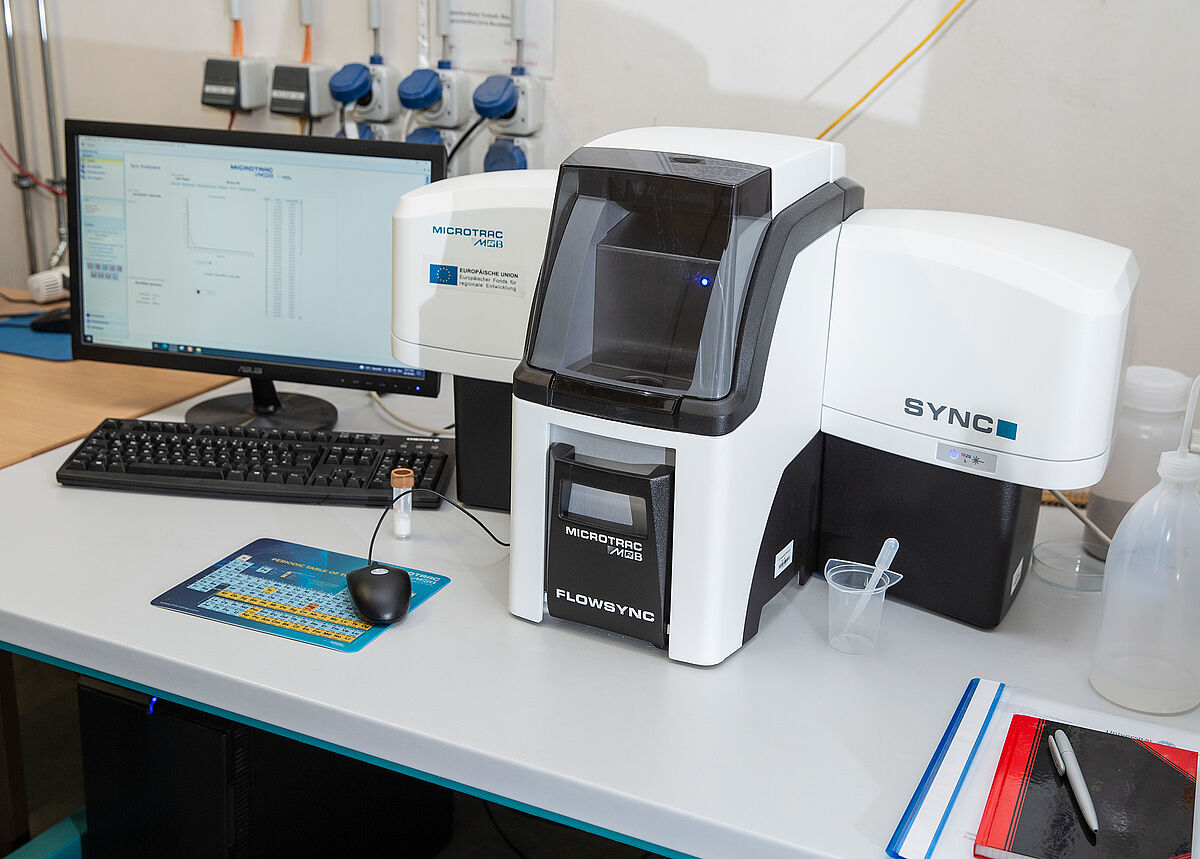

Particle Measurement Device

The particle measurement device is used to analyze particles in suspensions, emulsions and powders. Using a combination of static light scattering (laser diffraction) and dynamic image analysis, particles can be characterized regarding to their shape, size and distribution in a measurement range from 0.01 to 4,000 µm.

The instrument uses two detector arrays and three lasers (1x red, 2x blue) which detect the sample over an angular range from 0.02° to 163°. The measurement is based on the interaction of laser light with particles. The resulting control light pattern is evaluated using the Fraunhofer or Mie theory.

The integrated camera for dynamic image analysis according to ISO 13322-2 enables simultaneous measurement of particle size and shape. With up to 60 images per second, morphological parameters of the particles can be determined which are of high importance for processability in additive manufacturing:

- width, length, aspect ratio

- sphericity, concavity, convexity

- circularity

- symmetry

The dispersion module with an integrated ultrasonic probe enables the dissolution of agglomerates in suspensions or emulsions. For filling, venting, circulation as well as rinsing for wet measurement of particles an autofill pump is used, which can be connected with different media like water or solvent. With the help of the vortex movement in the circulation system, a constant movement of the homogeneously distributed particles in the liquid can be ensured.

The particle measurement device of the company Microtrac MRB is financially supported by the European Regional Development Fund (2014-2020).

Contact: Alexander Ahrend M.Sc.