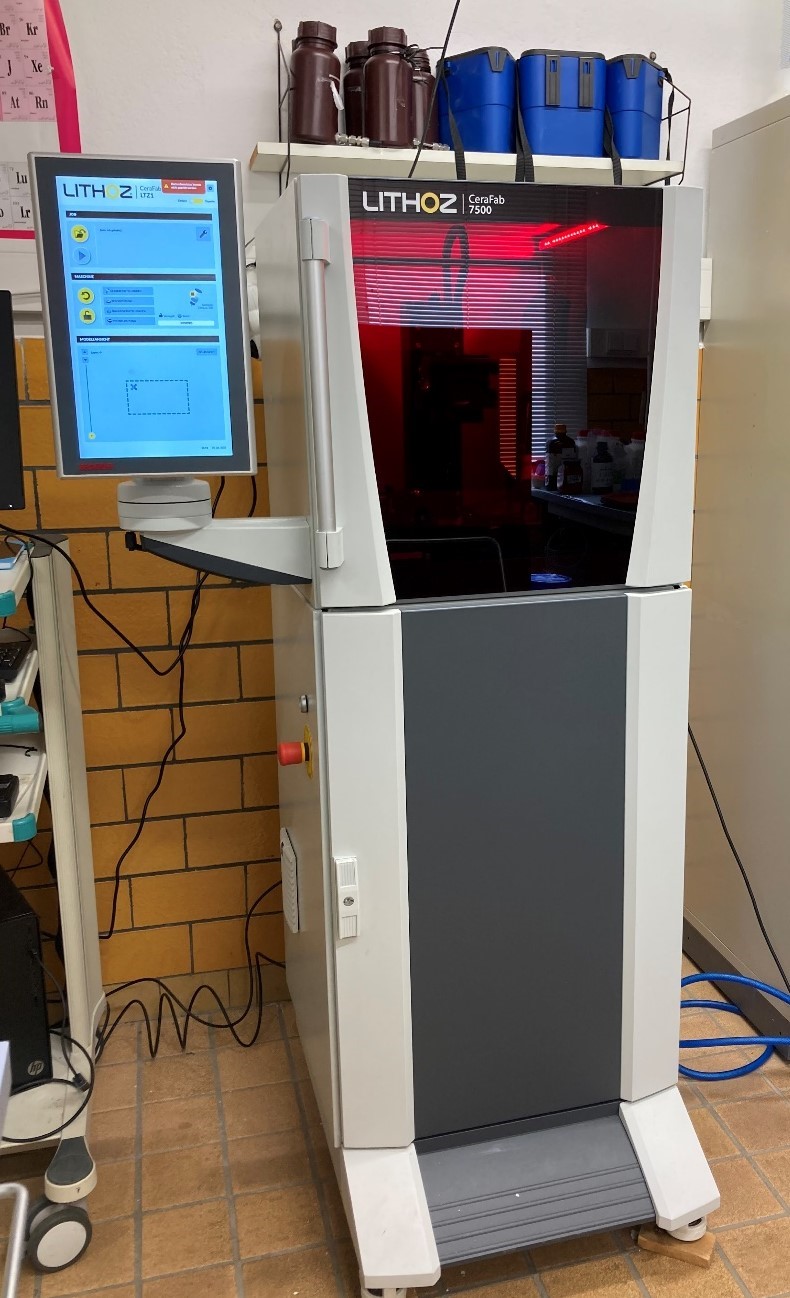

3D printer for loaded photopolymers

The CeraFab 7500 from Lithoz GmbH works according to the LCM (Lithography-based Ceramic Manufacturing) technology developed by Lithoz. The 3D component is made of particle-laden photopolymers in layers using a light-curing system. The production of compact and complex shapes is possible. In addition to their high density and structural resolution, the components that can be realised with this system also have a high surface quality and mechanical stability comparable to conventional manufacturing processes.

Selection of printable materials: Aluminium oxide, zirconia, silicon nitride, hydroxyapatite, tricalcium phosphate

As an open system, the 3D printer also enables the development and use of own materials.

The Chair of Microfluidics uses this facility for the construction of project-related prototypes (e. g. microsystems and medical technology), special components for test benches and for materials research.

The plant was procured with funding from the DFG and the state of Mecklenburg-Western Pomerania.

Technical parameters:

- Layer thickness: 10 - 100µm

- build platform: 76 x 43 x 170 mm

- Speed: 100 layers/h

- Resolution: 40µm (635dpi)

Contact: Benjamin Eichler