Microstereolithography

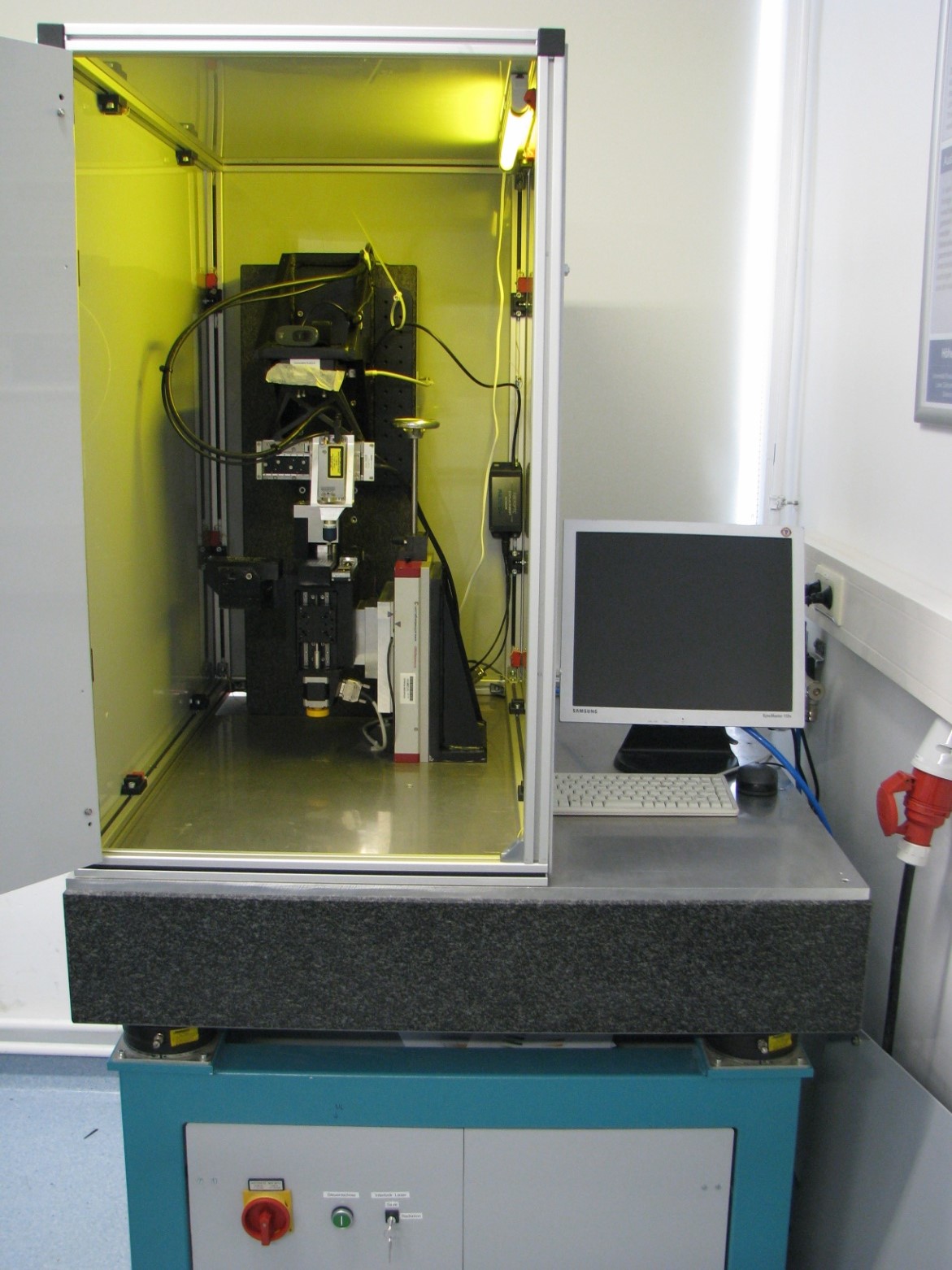

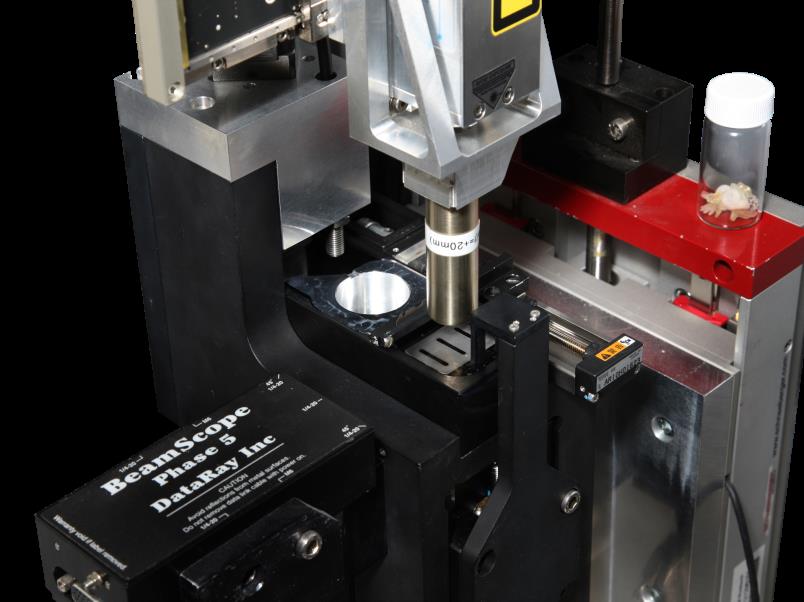

The micro stereolithography system developed at the chair is used for the production of micro structures and micro implants from new materials and biopolymers. The device works on the photopolymerization principle. A movable diode laser hardens individual volume elements of the irradiated polymer resin. The layers generated in this way are each lowered so that a new layer can be added. The principle of the system is characterized by the cost savings in the area of laser technology and the elimination of complex mirror mechanics. The laser modules can be replaced with little effort, which means that a large number of photopolymers can be processed.

Contact: Alexander Riess M.Sc.

| Building Space L/W/H: | 30 x 20 x 15 mm³ |

| Resolution: | 10 -30 µm |

| Layer thickness: | 30 µm |

| Build speed: | 400 mm/s |

| Data format: | Bitmap |

| Material: | Photopolymere (375 nm Wellenlänge), PEGDA, andere Acrylat- und Epoxydharze |