Joint project High-speed large capacity printer

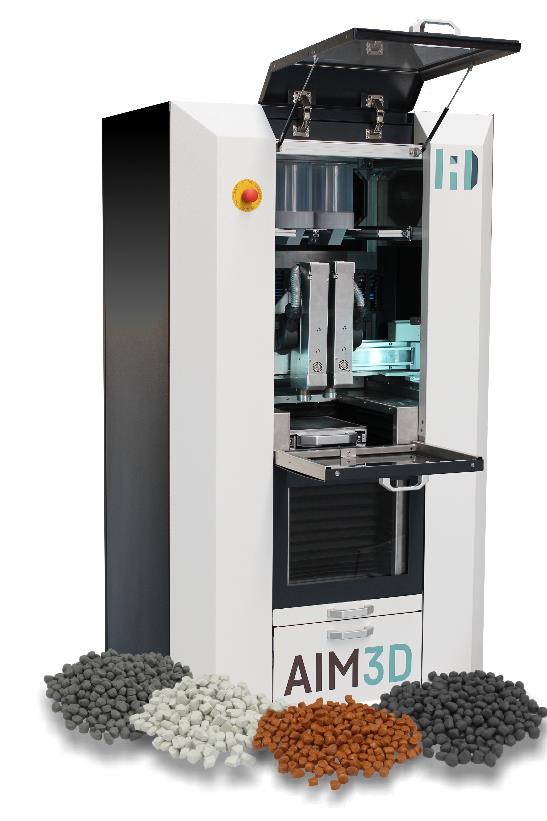

In the joint project, a high-speed large-capacity printer for processing ceramic feedstocks in the CEM-process will be developed in close cooperation with the company AIM3D GmbH.

An additive manufacturing process is being developed which enables industrial users to produce a few large or many small ceramic components at the same time. In contrast to conventional production, the costs for small quantities can be drastically reduced. In addition, the additive manufacturing process enables shapes that were previously impossible or only possible with great effort, such as cavities or special infill structures for weight reduction.

The joint project can be divided into three task packages:

- Feedstock development, production and testing

- CEM-3D-print parameter development and component manufacturing

- Implementation of an intelligent print head

For the development of process parameters, commercial CIM-feedstocks are examined for their processability. In addition to the analysis of the printed components, the debindering and sintering behaviour of the materials is being investigated. In addition to the use of conventional CIM-feedstocks, an own ceramic feedstock is being developed and will be examined with various mechanical testing methods.

The aim of this joint project is a stable printing process of components with certain geometric and mechanical properties. In addition, theoretical and experimental investigations are carried out to further develop a print head for the CEM-process.

Contact: Alexander Ahrend M.Sc.; Tim Dreier M.Sc.; Sofiane Bouhedma M.Sc.

Duration: 10/2019 - 02/2023

Funded by: Ministerium für Wirtschaft, Arbeit und Gesundheit (M-V), Operationelles Programm für den Europäischen Fonds für regionale Entwicklung in Mecklenburg-Vorpommern in der Förderperiode 2014 bis 2020 (EFRE-OP M-V)

Cooperation: AIM3D GmbH