Cooperative project 6: biotechnological micro annular gear pumps

Subprojekt 6.2: Development of a laser-based microstructuring of slide bearings fort he tribological optimization of micro annular gear pumps

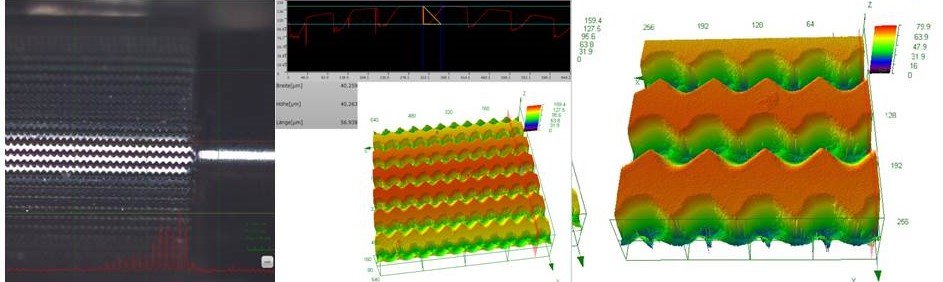

In the cooperative project „biotechnological micro annular gear pumps“ of the regional growth project MikroLas, micro gear pumps with high requirements are developed for the diagnostic market and for manufacuturers of pharmaceutical products. For example, small to very small amounts of highly aggressive fluids should be able to precisely dosed or continuously promoted for the use in various processes. Furthermore the micro pumps have to fulfill the level of hygiene and certifications, which required for the specific use in biotechnical applications. In addition to the cleaning time for the customer, the focus is on the pump design with regard to the Hygienic Design with functionalized surfaces and the selection of biocompatible materials including adapted joining techniques. In subproject 6.2, an increase in liefetime of the friction combination shaft-bearing is intended. For this purpose, the tribological properties (friction coefficient and wear) of the shaft-bearing pairing should be optimized by the application of microstructures by use of ultrashort laser pulses. If it is possible to minimize wear, an increase in lifetime of the annular gear pumps and, despite higher acquisition costs, increased competitiveness of the products can be expected.

Contact: Georg Schnell M.Sc.

Project term: 9/2017-12/2020

Fundet by: PtJ-Projektträger Jülich

Cooperation: HNP Mikrosysteme GmbH, Schwerin