Development of materials and printhead for the composite extrusion modeling

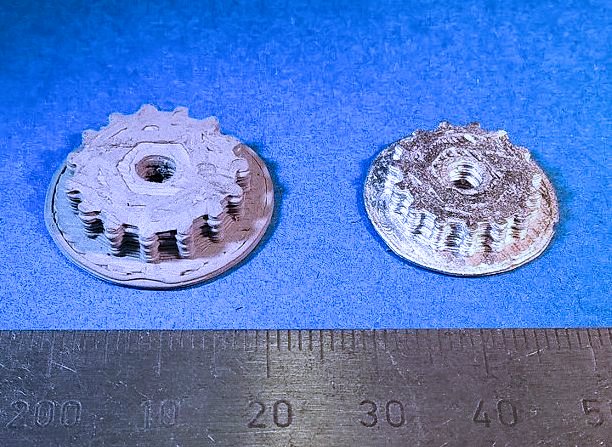

The aim of this project is the development of an additive manufacturing process (3-D printing) for the manufacturing of metal components (Composite Extrusion Modeling). At first, a cost-effective extrusion process, similar to the fused deposition modeling (FDM) was used for generating green parts from a metal composite. The components are consecutively taken from the printer and sintered in a sinter oven. This way, a solid metallic material is realized. Due to the fact that convetional FDM-systems as well as the composites are not usable in this process, yet, the cooperation with the partners will lead to the development of a functional extrusion system, containing the print head and the material supply.

Contact: Clemens Lieberwirth M.Sc.

Laufzeit: 03/2015 - 31.08.2017

Förderung: Bundesministerium für Wirtschaft und Energie (BMWi)

Koorperation: Bernhardt Kunststoffverarbeitung GmbH 3dk.berlin