RESPONSE: 3D printing of functionalized biomaterials

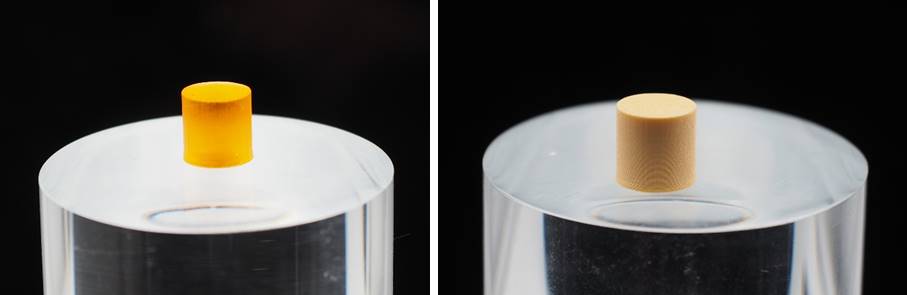

LFM participates in the research network RESPONSE – Partnership for Innovation in Implant Technology. The research field is the 3D printing of functionalized biomaterials via various 3D printing technologies as Composite Extrusion Modeling (CEM) and Digital Light Processing (DLP). Utilizing CEM, there are investigations of processing biodegradable metal matrix composites (BMMC). In this study, there is a cooperation with the Chair of Material Science of the University of Rostock. The work focuses on CEM-parameters for stable 3D printing, and optimal metal-polymer-interface has to be developed. It is investigated, if the polymeric component's crystallization behaviour can be influenced in the printing process and via post-processing, for example, for tailoring the polymer's degradation behaviour. Utilizing DLP the work focusses particle incorporation and stimuli-responsive polymers. The piezoelectric behaviour of DLP-printable photopolymers is adjusted via specific ceramic particles. As well, for example, thermoresponsive polymers will be 3D-printed for tailoring drug release behaviour.

Funding: Federal Ministry of Education and Research (Bundesministerium für Bildung und Forschung (BMBF)) in the programm Zwanzig20 – Partnership for Innovation

Correspondence: Dipl.-Ing. Robert Mau

Research network: RESPONSE – Partnership for Innovations in Implant Technology